If you are interested in some of our products, please feel free to visit our website or contact us for detailed information.

The choice of covering material in mechanical covered yarn has a significant impact on the durability and performance of the yarn in end-use applications. Here's how:

1.Abrasion Resistance: The abrasion resistance of the covering material is a fundamental factor in determining the mechanical covered yarn's lifespan in applications subjected to friction or wear. For instance, in the production of workwear or conveyor belts, a highly abrasion-resistant covering material, such as nylon or polyester, is often preferred to ensure the yarn can withstand constant rubbing against surfaces without deteriorating or fraying.

2.Tensile Strength: The tensile strength of the covering material directly contributes to the overall tensile strength of the mechanical covered yarn. In scenarios where strength is paramount, such as in safety harnesses or high-tension cables, selecting a covering material with exceptional tensile strength, such as aramid fibers (e.g., Kevlar), is essential to ensure the yarn can endure heavy loads and maintain structural integrity over time.

3.Chemical Resistance: In chemical and industrial applications, the covering material's resistance to specific chemicals is vital to prevent degradation or corrosion of the yarn. For example, in chemical hoses or protective suits for hazardous environments, covering materials with resistance to acids, alkalis, or solvents are chosen to ensure the yarn remains functional and safe.

4.Temperature Resistance: In extreme temperature environments, like automotive engine compartments or aerospace components, the choice of covering material must consider its ability to maintain mechanical properties and structural integrity at high or low temperatures. Heat-resistant polymers or ceramic fibers may be preferred for applications requiring thermal stability.

5.UV Resistance: When the mechanical covered yarn will be exposed to sunlight or UV radiation, UV-resistant covering materials are essential to prevent degradation, color fading, or loss of mechanical properties. This is particularly important in outdoor textiles, awnings, and sailcloth applications.

6.Moisture Resistance: For applications in which moisture exposure is likely, such as marine ropes or outdoor sporting equipment, selecting covering materials with moisture-repellent properties or the ability to wick moisture away from the core yarn can prevent issues like mildew growth and yarn weakening due to water absorption.

7.Flexibility: The covering material's flexibility is crucial for applications requiring the yarn to bend, twist, or stretch. In products like medical textiles, where flexibility is essential for patient comfort, or in flexible hoses for machinery, the covering material's pliability and elasticity are carefully considered to ensure the yarn can meet the demands of the application.

8.Aesthetic Properties: In fashion and interior design applications, the appearance and texture of the covering material play a pivotal role in the final product's visual appeal. High-quality, aesthetically pleasing covering materials are selected to create textiles that meet design and fashion standards.

9.Weight and Density: For lightweight textiles or aerospace components, minimizing weight is critical. Covering materials with lower density are preferred to reduce the overall weight of the mechanical covered yarn while maintaining necessary performance characteristics.

10.Cost: Cost considerations are always present in material selection. Manufacturers must balance performance requirements with budget constraints, and this often influences the choice of covering material. In some cases, a lower-cost covering material with adequate properties may be chosen to make the final product economically viable.

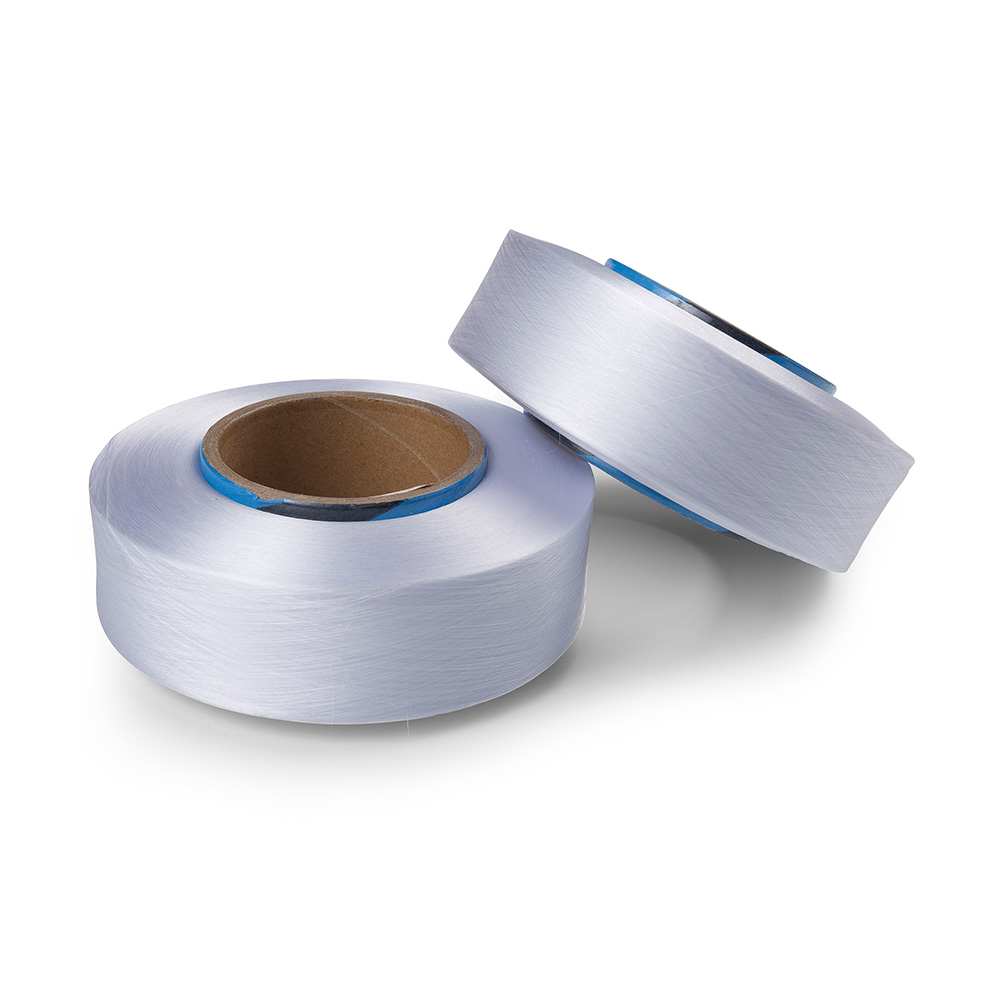

Mechanical covered yarn (SCY) is a type of yarn that continuously rotates and wraps the wrapped fiber filament onto the uniformly drawn core spandex. It is twisted and has a twist (TPM), and its main characteristic is its flat and straight fabric style.

English

English Español

Español