If you are interested in some of our products, please feel free to visit our website or contact us for detailed information.

Moisture Resistance: Rubber yarns are inherently hydrophobic, meaning they repel water. This property is crucial in preventing moisture absorption, which can weaken fibers and lead to degradation over time. Unlike natural fibers that may absorb water and become brittle or prone to mold growth, rubber yarns maintain their structural integrity and elasticity even in humid environments or when exposed to moisture. This resistance ensures consistent performance in applications where exposure to water is frequent, such as swimwear, outdoor gear, and medical textiles that require cleanliness and moisture management.

Temperature Stability: Rubber yarns exhibit remarkable thermal stability, retaining their elasticity and mechanical properties across a broad range of temperatures. This characteristic is vital for applications spanning extreme climates—from freezing temperatures to high heat environments—where materials must withstand thermal expansion and contraction without compromising performance. Whether used in cold-resistant apparel, automotive components subject to engine heat, or outdoor furniture exposed to seasonal temperature variations, rubber yarns provide reliability and longevity under diverse thermal conditions.

UV Resistance: Many rubber yarn formulations are engineered with UV stabilizers to enhance their resistance to ultraviolet radiation. UV resistance is critical in outdoor applications where prolonged exposure to sunlight can accelerate material degradation. By minimizing UV-induced degradation such as color fading, embrittlement, and loss of elasticity, UV-resistant rubber yarns prolong the lifespan of products like awnings, outdoor furniture, and sports equipment. This durability ensures that the aesthetic and functional qualities of these items remain intact despite continuous exposure to sunlight.

Chemical Resistance: Depending on their formulation, rubber yarns can exhibit varying degrees of resistance to chemicals such as oils, acids, alkalis, and solvents. This chemical resistance makes them suitable for applications where exposure to harsh substances is common, such as industrial seals, protective clothing, and automotive components. By resisting chemical degradation and maintaining their physical properties, rubber yarns ensure long-term performance and reliability in environments where chemical exposure could otherwise compromise material integrity and functionality.

Abrasion Resistance: Rubber yarns are renowned for their exceptional abrasion resistance, stemming from their tough yet flexible nature. This durability allows rubber yarns to withstand frictional wear and tear without significant damage or deterioration. This makes them ideal for high-wear applications such as sportswear, footwear, and industrial textiles where prolonged contact with abrasive surfaces could otherwise cause premature wear and reduce product lifespan. The ability to maintain integrity under abrasive conditions ensures that products made with rubber yarns remain robust and functional throughout their intended use.

Flexibility and Elasticity: Rubber yarns exhibit outstanding elasticity and flexibility, retaining these properties even after repeated cycles of stretching and relaxation. This resilience is crucial in applications requiring dynamic movement and stretch recovery, such as athletic apparel, medical compression garments, and stretch fabrics. By maintaining elasticity over time, rubber yarns provide comfort, support, and freedom of movement to users while ensuring that garments and products retain their shape and performance characteristics throughout their lifespan.

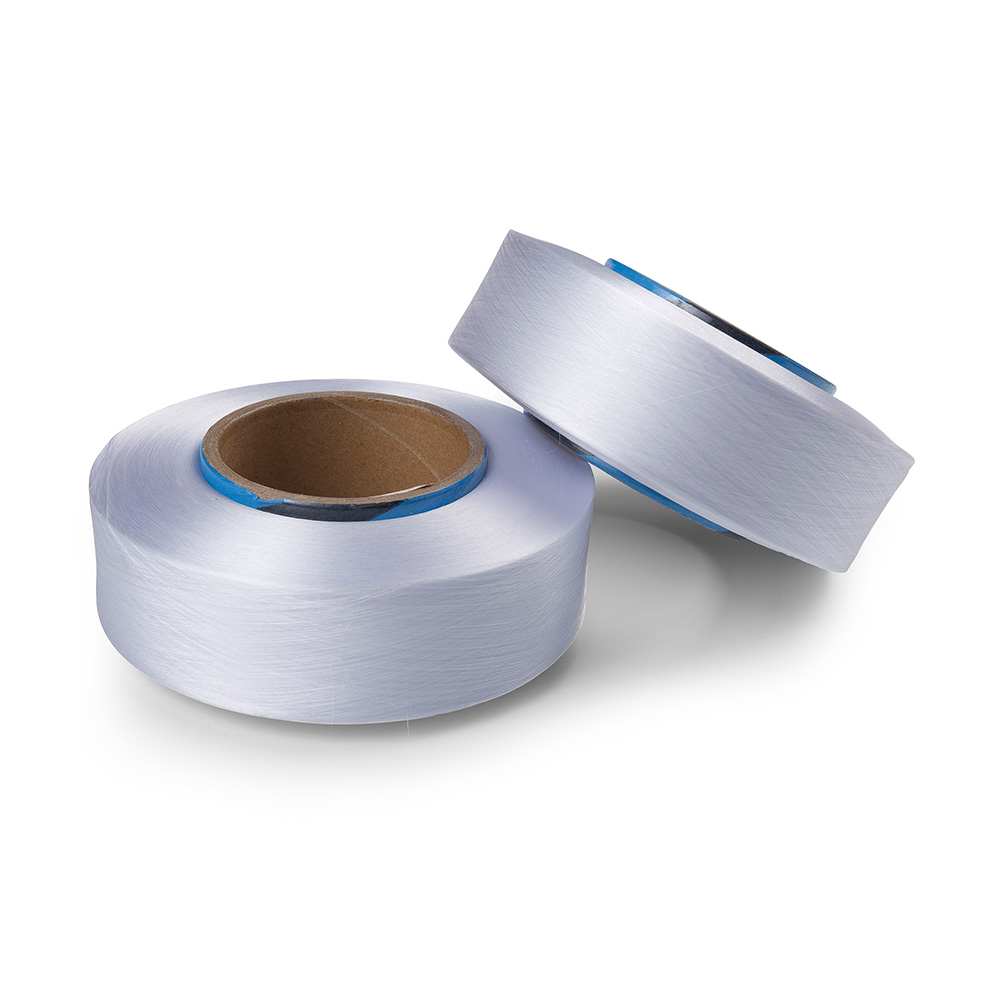

Rubber Spandex Mechanical Covered Nylon DTY Yarn

Rubber covered yarn is made of high-quality imported A-grade latex yarn as the core, and high-quality double-stranded fiber yarn (polyester or nylon yarn), which is double coated.

English

English Español

Español